Rubber engine mounts !

Vertical Twin or any bike that vibrates too much – an easy fix !

When I took off the stock bars and put on lower ones, it got worse – the aftermarket bars were thinner/lighter. Changing grips did not help much. Adding weights to the bars helped some.

Yesterday I rubber mounted the upper engine mount on the CM400. This morning I went up on I95 to test it. The difference was unbelievable – rubber-mounting the upper engine mount cut most of the vibration felt through the handlebars. It felt like a different bike (I have never even gone 80 mph (before today) on this bike.)

I bought this bike in 2009 and I can’t believe I did not think of this until now.

I just used an old motorcycle inner tube – fold it to make two layers – but a better choice would be neoprene washers.

For upper motor mount: neoprene washers. For lower front engine mount: nylon washers.

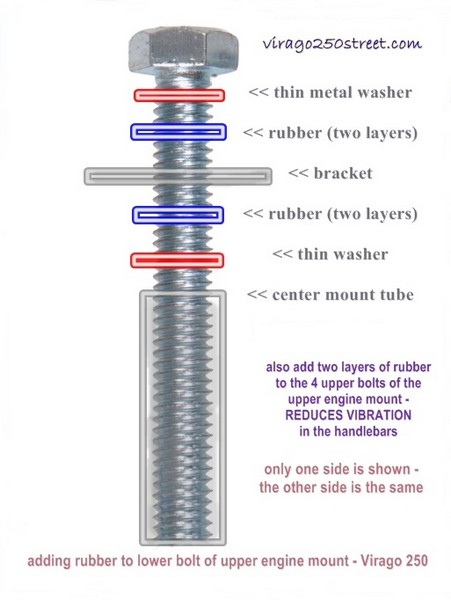

In order, here is what goes on each side of the two upper bolts of the upper engine mount: thin metal washer, rubber (two layers), bracket, rubber (two layers). If the rubber or washers are too thick, the bolt will be too short.

In order, here is what goes on each side of the lower bolt of the upper engine mount: thin metal washer, rubber (two layers), bracket, rubber (two layers), thin washer. The last thin washer is very important as it goes against the center mount tube. The center tube mounting tube is very thin, so the contact point with the rubber would not be enough – a thin metal washer is required. If the rubber or washers are too thick, the bolt will be too short. The stock bolt is about 4.25 inches long, if you buy a bolt about 6 inches long, you can use four layers of rubber instead of two. I am going to try this next.

I used a 3/8 inch x 6 inch long bolt. It was 7/8″ longer than needed, which leaves room if I want to add more rubber pieces. A 3/8 x 5 inch bolt would work, if you use thin washers. I added more rubber pieces so now the lower bolt has four layers of rubber.

A good size for the rubber pieces is 1 to 1.5 inches diameter – round. Make a hole that will easily slip over the 3/8″ bolt.

The metal washers should be 1 inch or slightly bigger.

A perfect choice would be 1.25 inch round rubber pieces and 1.25 inch metal washers.

Do not over tighten the lower bolt – lightly snug is good – use two nuts on the lower bolt.

For the rubber pieces, what you want is a dense, hard rubber or neoprene. Motorcycle inner tube is a good second choice. An old mouse pad will work fine, but in maybe six months it could become compressed and will be less effective at reducing vibration.

Lower front engine mount

Adding rubber to the lower front engine mount is more difficult than the top one – do the top mount first so you will get a little practice before you work on the lower front engine mount.

First, put a floor jack under the front of the engine and give it a few pumps. If you don’t support the front of the engine, it will drop about 4 mm.

The nylon washer between the bracket and the frame (or engine) is the most important one, and I was able to fit only one side on two of them. If you stretch the bracket open you would be able to fit both sides on all four bolts. Using an inner tube for the rubber is not good enough for this engine mount, you really need a tougher material like nylon or the reinforced ones at Autozone (I am going to try those next). The four bolts need to be tightened very tightly, so normal rubber will not hold up.

The bolts are not very long, so the metal washers need to be thin. The metal washer needs to cover the rubber washer completely (or close to it).

For the lower front engine mount, nylon washers is a good choice. A regular rubber washer will not last long in this usage – a better choice would be nylon, neoprene, or silicone. They do not absorb vibration as well but they are more durable and you can tighten them more. I bought 10mm x 20mm x 2mm black nylon washers on eBay – I got 50 for $2.49 USD plus $2.99 USD shipping.

The ideal washer would be

10mm inside diameter ….. 20mm outside diameter … 2mm thickness

or 3/8″ inside diameter ….. 3/4 or 7/8″ outside diameter … 1/16″ thickness

I am buying these at Home Depot: 3/8 in. x 13/16 in. Black Neoprene Washer model # 815758 (3-Pack $1.18; need 4 packs) by Everbilt (1/16 or 1.6mm thick)

Nice mod dude! Did you double nut it so you could leave a little slack and not have it come loose? Or is that mounting tube threaded forcing you to sock the whole stack down tight?

Hi Doug,

Thanks for the comment. Yes, I did double-nut it. You have to leave it a little loose so that the bolt is supported by the rubber.

-Les S.

How do these mods affect handling?

Hi Alan,

I have not noticed any difference in the handling.

My guess would be not much difference at a moderate pace and possibly some difference at a higher pace.

I did not modify the rear lower mount and on the front lower mount, the rubber I added is pretty thin – so if there is any effect on handling, it is probably minimal.

Regards,

Les

I will say this about my cm400 aftermarket straight V-d handlebars and a crash bar mounted to the engine mount bolts keeps me almost vibration free and crash bar looks cool and protects your front end but with that crash bar I would definetely need 8in bolts to add rubber hardly any thread left after being fed through the mount and bar.

Great idea. It’s kind of like the difference between a triumph and a Norton. Norton was rubber mounted. Made a big difference.

I have a 1981 cm400a cannot wait to try it.

Thanks

Let me know how it goes!